Our Luxury Process

Every stage of our production reflects precision craftsmanship, advanced innovation, and uncompromised quality control — delivering excellence with refined elegance.

Refined Workflow

- ✔ Curated Raw Material

- ✔ Precision Weaving

- ✔ Premium Finishing

- ✔ Elite Quality Check

DYEING

The weavers procure the yarns from nearby places. The yarn is dyed to the desired colour and left to dry.

WARPING

This is the process where the base threads are set. Every woven product has a base thread in white as you can see in the pictures. This has to be prepared which is done in this process

SPINNING

Once the dyed yarn is read, it needs to be wound around a spindle or be made in bundles. This is done using the charkas which works with a pedal. This process helps make the spools of thread with which the weaving is done.

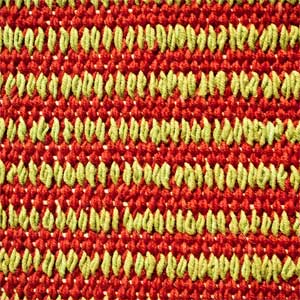

WEAVING

Once the spindles, spools and are ready, the base threads are mounted on the main loom. With the help of the spindle, spool and the base threads, the magical weaves are woven by hand.

Different Types Weaves

FRAME

Uses two shuttles. One does the base colour weaving and the other does the accent colours. The changes in the drafting technique makes the unique weave.

INLAY

Involves most handwork as every weave is done by hand. The threads are wound in and around another row of threads. Minimum use of the shuttle.

CLOTH WEAVE

This method is mainly hand done as the weaves are crossed. It is a tedious process.

PLAIN

Done completely with the shuttle. Fastest method of weaving.

PAYAL

The shuttle work is mainly for the base weave. The hand work in this is the most complicated It involves tying a knot for every weave and cutting each thread at the top.

COURDROY

This method is mainly hand done as the weaves are crossed. It is a tedious process.